Manufacturing

A significant amount of work in design, physical testing and prototyping is required before devices will be ready for serial production and commercial deployment. The focus of research and development is likely to evolve from proving device concepts to demonstrating reliability,understanding the operation of multiple devices within arrays and achieving lifetime cost savings through design for production. Providing suffcient investment is made in these activities, significant improvements in device design and operation could be made in the next few years.It is likely that most device manufacturers will specify and purchase main components and assemble them into finished devices. The balance between in-house manufacturing (and associated facilities) and outsourcing is likely to evolve as demand for generation devices increases.

The wave or tidal stream energy generation device is at the heart of a generation project. All other planning activity and development of supporting infrastructure is focussed on enabling the device to extract energy from the environment safely, reliably and at the right cost over a design life of around 25 years. A number of first-generation prototypes have been tested over the last decade and by 2011 it is estimated that more than ten such devices will be undergoing full testing programmes around the world. A significant proportion of this testing is being carried out at EMEC in Orkney.

Wave and tidal stream energy devices generally consist of a prime-mover element coupled to a power take-off arrangement, a reaction system and a control system. A range of different device technologies are currently under development and several full-scale prototype devices are now being tested. The next step is to demonstrate small arrays of devices, either as an initial phase of the Pentland Firth and Orkney waters projects or elsewhere in the UK oroverseas.

Wave energy devices

Waves are created by the action of wind on the surface of the sea. Initially acting on small perturbations of the surface, continued wind action grows these small disturbances into fully developed waves. The propagation of waves in terms of their size and energy content depends on the duration and speed of the wind and the distance over which the wind acts (the fetch). Wave characteristics are strongly affected by water depth, sea-bed bathymetry and diffraction effects around obstacles.

Tidal energy devices

The gravitational forces of the earth, moon and sun cause the natural rise and fall of sea levels and the consequential flow of significant amounts of water back and forth each tide in coastal areas. Tidal stream energy devices capture energy from this flow in a similar way to the manner in which wind turbines capture energy from the flow of air, the amount of energy captured being a function of the flow speed and intercepted area. However, due to water being much denser than air, a smaller machine is needed for an equivalent energy capture.

Device manufacture procurement

Device manufacturers are likely to assemble their devices from bought-in components. Some are assembling prototype devices at present and a number of manufacturers each envisage batch production of around 20-50 devices per year by the middle of the decade.The number and type of components required varies with the type of device. In most cases however, components include low-value off-the-shelf items, higher-value catalogue items manufactured to order and both small and large items manufactured to drawing and/or specification.

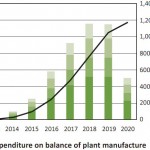

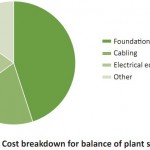

Balance of plant manufacture

Although wave and tidal devices are at the heart of each project, balance of plant items make up asignificant part of the capital cost and are required to make operation safe and reliable. Balance of plant items may be subjected to the same extreme environments as devices and it is expected that technology development will continue over the next years in order to deliver the required functionality at optimum cost. Adaptation of existing technology is likely to be required to suit specific applications and varying site conditions.

Balance of plant manufacture procurement

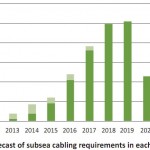

Given the novelty of wave and tidal stream project development, there is not yet a single pattern of procurement or supply of balance of plant items. However, it can be expected that electrical and cabling systems will be procured by the project developer with input from the device manufacturer in order to ensure proper interfacing with devices. Foundations, where they do not make-up an integral part of the device, may be designed in conjunction with the device manufacturer but procurement may again be managed by the project developer.

Procurement activities are likely to commence in the development and consenting stage, with orders being placed around one to two years before installation. For some parts such as electrical transformers and subsea cables, earlier procurement may be required due to typical component lead-times

To view further detail please read the Content Source: The Crown Estate, May 2011 – Wave and Tidal energy in the Pentland Firth and Orkney waters: How the projects could be built.